|

| February 09, 2016 | Volume 12 Issue 06 |

Designfax weekly eMagazine

Archives

Partners

Manufacturing Center

Product Spotlight

Modern Applications News

Metalworking Ideas For

Today's Job Shops

Tooling and Production

Strategies for large

metalworking plants

Supersize wind blades could lead to more offshore energy in U.S.

A new design for gigantic blades almost two football fields long could help bring offshore 50-megawatt (MW) wind turbines to the United States and the world.

Sandia National Laboratories' research on the extreme-scale Segmented Ultralight Morphing Rotor (SUMR) is funded by the Department of Energy's (DOE) Advanced Research Projects Agency-Energy program. The challenge: Design a low-cost offshore 50-MW turbine requiring a rotor blade more than 650 ft (200 m) long, two and a half times longer than any existing wind blade.

The team is led by the University of Virginia and includes Sandia and researchers from the University of Illinois, the University of Colorado, the Colorado School of Mines and the National Renewable Energy Laboratory. Corporate advisory partners include Dominion Resources, General Electric Co., Siemens AG, and Vestas Wind Systems.

Todd Griffith shows a cross-section of a 50-m blade design prototype, which is part of the pathway to the 200-m exascale turbines being planned under a DOE ARPA-E-funded program. The huge turbines could be the basis for 50-MW offshore wind energy installations in the years ahead. [Photo by Randy Montoya]

"Exascale turbines take advantage of economies of scale," said Todd Griffith, lead blade designer on the project and technical lead for Sandia's Offshore Wind Energy Program.

Sandia's previous work on 13-MW systems uses 100-m blades (328 ft) on which the initial SUMR designs are based. While a 50-MW horizontal wind turbine is well beyond the size of any current design, studies show that load alignment can dramatically reduce peak stresses and fatigue on the rotor blades. This reduces costs and allows construction of blades big enough for a 50-MW system.

Most current U.S. wind turbines produce power in the 1- to 2-MW range, with blades about 165 ft (50 m) long, while the largest commercially available turbine is rated at 8 MW with blades 262 ft (80 m) long.

"The U.S. has great offshore wind energy potential, but offshore installations are expensive, so larger turbines are needed to capture that energy at an affordable cost," Griffith said. Barriers remain before designers can scale up to a 50-MW turbine -- more than six times the power output of the largest current turbines.

"Conventional upwind blades are expensive to manufacture, deploy, and maintain beyond 10 to 15 MW. They must be stiff to avoid fatigue and eliminate the risk of tower strikes in strong gusts. Those stiff blades are heavy, and their mass, which is directly related to cost, becomes even more problematic at the extreme scale due to gravity loads and other changes," Griffith said.

He said the new blades could be more easily and cost-effectively manufactured in segments, avoiding the unprecedented-scale equipment needed for transport and assembly of blades built as single units.

The exascale turbines would be sited downwind, unlike conventional turbines that are configured with the rotor blades upwind of the tower.

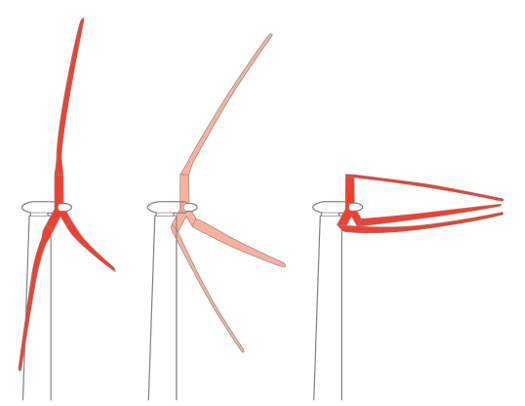

The Segmented Ultralight Morphing Rotor (SUMR).[Illustration courtesy of TrevorJohnston.com/Popular Science]

Sandia's 100-m blade is the basis for the Segmented Ultralight Morphing Rotor (SUMR), a new low-cost offshore 50-MW wind turbine. At dangerous wind speeds, the blades are stowed and aligned with the wind direction, reducing the risk of damage. At lower wind speeds, the blades spread out more to maximize energy production.

SUMR's load-alignment is bio-inspired by the way palm trees move in storms. The lightweight, segmented trunk approximates a series of cylindrical shells that bend in the wind while retaining segment stiffness. This alignment radically reduces the mass required for blade stiffening by reducing the forces on the blades using the palm-tree inspired load-alignment approach.

Segmented turbine blades have a significant advantage in parts of the world at risk for severe storms, such as hurricanes, where offshore turbines must withstand tremendous wind speeds over 200 mph. The blades align themselves to reduce cantilever forces on the blade through a trunnion hinge near the hub that responds to changes in wind speed.

"At dangerous wind speeds, the blades are stowed and aligned with the wind direction, reducing the risk of damage. At lower wind speeds, the blades spread out more to maximize energy production." Griffith said.

Moving toward exascale turbines could be an important way to meet DOE's goal of providing 20 percent of the nation's energy from wind by 2030, as detailed in its recent Wind Vision Report.

Sandia National Laboratories is a multi-program laboratory operated by Sandia Corporation, a wholly owned subsidiary of Lockheed Martin Corp., for the U.S. Department of Energy's National Nuclear Security Administration. With main facilities in Albuquerque, NM, and Livermore, CA, Sandia has major R&D responsibilities in national security, energy, and environmental technologies and economic competitiveness.

Source: Sandia

Published February 2016

Rate this article

View our terms of use and privacy policy